The CFD simulations were automated using a Python script and were performed using the incompressible, steady-state RANS solver with porous media, and the k-omega SST turbulence model.The previous posts have discussed the meshing requirements that we need to pay attention to for a valid result. The filter assembly geometry was created in Caedium Professional. Pressure Iso-SurfacesFilter Assembly CFD simulation for 0.06 m 3/s flow rateĬlipped Pressure Iso-SurfacesFilter Assembly CFD simulation for 0.06 m 3/s flow rate Notes Velocity Iso-SurfacesFilter Assembly CFD simulation for 0.06 m 3/s flow rateĬlipped Velocity Iso-SurfacesFilter Assembly CFD simulation for 0.06 m 3/s flow rate Velocity VectorsFilter Assembly CFD simulation for 0.06 m 3/s flow rateĬlipped Velocity VectorsFilter Assembly CFD simulation for 0.06 m 3/s flow rate Manifold StreamlinesFilter Assembly CFD simulation for 0.06 m 3/s flow rate Pressure Drop for Cyclone + Filters and Pressure Rise for BlowerIntersection indicates operating conditions Flow Visualizationįilter Box StreamlinesFilter Assembly CFD simulation for 0.06 m 3/s flow rate Note this does not account for the length or type of hose connected to the cyclone inlet, which Matthias tells me contributes more pressure drop than the filters. The intersect of the total pressure drop curve with the blower's fan curve gives the operating conditions at a flow rate of 0.063 m 3/s and a pressure rise of 2900 N/m 2.

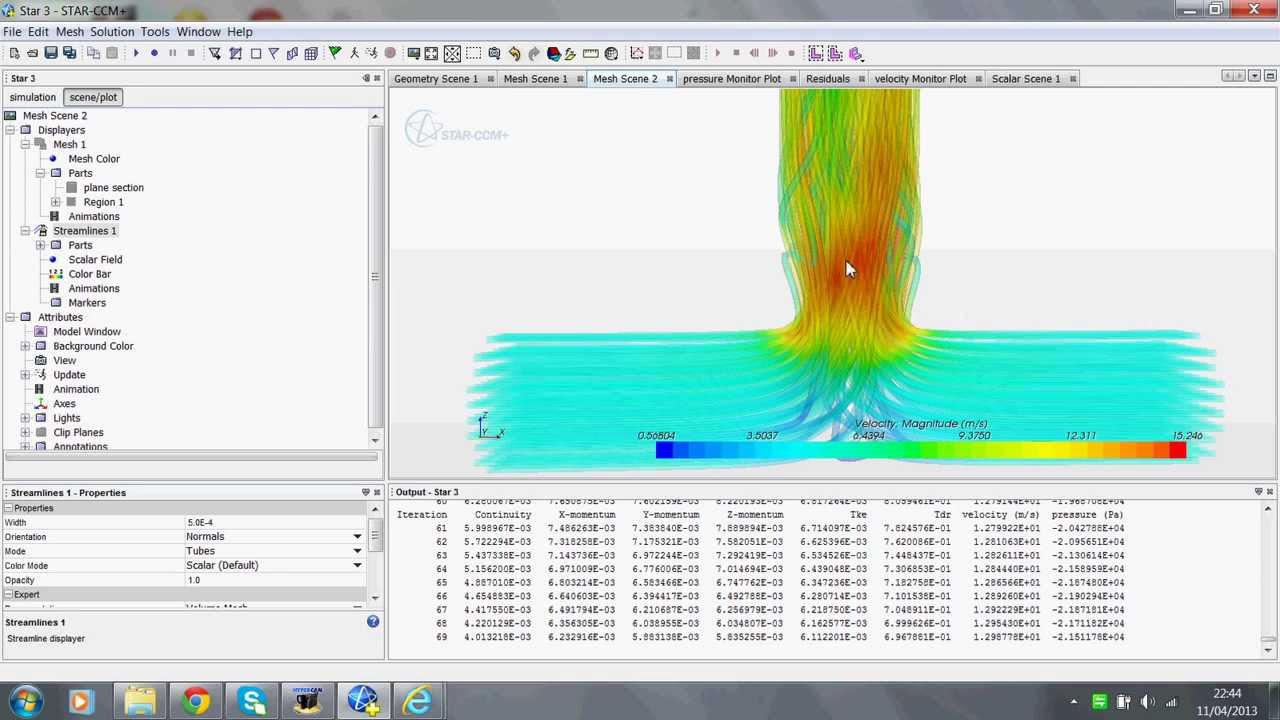

At 0.06 m 3/s the pressure drop for the filters is only 4% that of the cyclone.Ĭomparison of Pressure Drop for Cyclone, Filters, and Cyclone + Filters vs Flow RateĬombining the pressure drops for the filters and for the cyclone gives the total pressure drop curve. However, notice that the pressure drop for the filters is insignificant when compared to the pressure drop for the cyclone. The results show that as the flow rate increases through the filters the pressure drop also increases, as we found for the cyclone. Pressure Drop vs Volume Flow Rate for the Filter Assembly Summary Hence, for this study we ran 9 simulations in the range 0.01 - 0.1 m 3/s. Recall our previous CFD simulation for the cyclone revealed that the operating condition for the complete system should correspond to a flow rate of less than 0.065 m 3/s. However, the range over which the permeability changes for the flow rate we are considering is small, so for this study we will assume it is constant. Permeability is a function of volume flow rate and pressure drop, so ideally it needs to be modified for each flow condition. Assuming Darcy's Law and assuming the filters conform to the HEPA standard we find that the permeability is 3.79 x 10 -5 m 2. In the complete system the manifold outlet is coupled directly to the inlet of the blower, hence its off-center position.ĬFD Filter Assembly Flow Domain Performance Testįor porous media we need to define the permeability of the filters in our model. Once the flow leaves the two filter cores it recombines into a single outlet through a manifold. The geometry was created from scratch using Matthias' plans.ĭust Collector Filter AssemblySketchUp Assembly Model The twin filters were modeled as porous media using a multi-volume flow domain where the filters are represented as separate volumes. The filters remove fine particles that escape the cyclone, leaving the air to pass through the blower and exit to the atmosphere.ĬFD Simulation of a Filter Assembly for a Dust Collector 3D Model Construction After using Computational Fluid Dynamics (CFD) to simulate the blower and cyclone in Matthias Wandel's "Small Dust Collector" we next turn our attention to the last remaining major component - the twin filter assembly.

0 kommentar(er)

0 kommentar(er)